Introduction

The world faces significant economic challenges in 2023, heavily impacted by the lingering effects of the COVID-19 pandemic. Unemployment rates remain high, inflation is a growing concern, and various industries struggle to recover.

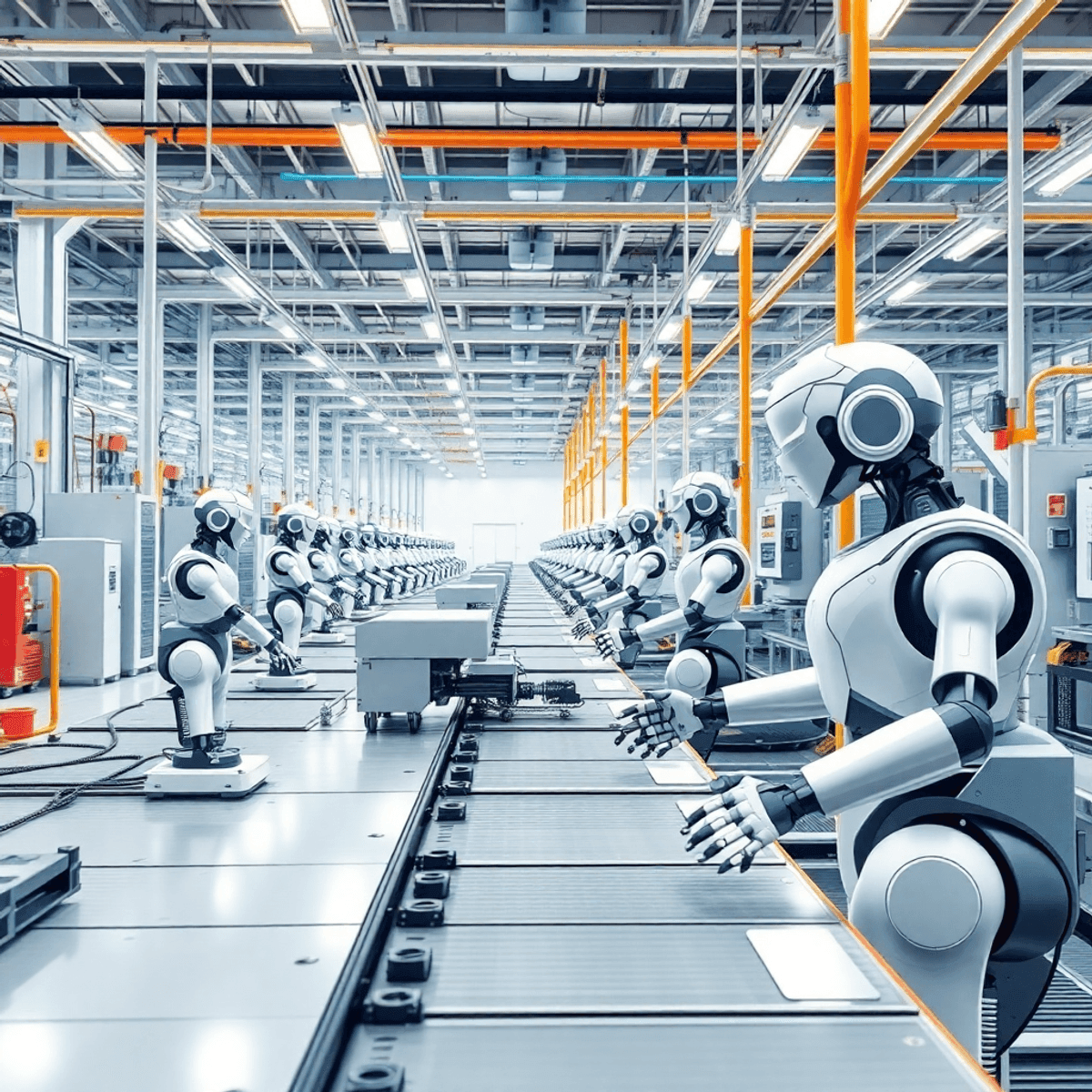

Robots have emerged as a critical solution in addressing these issues.

Key roles include:

- Increasing efficiency in manufacturing

- Filling labor shortages in service sectors

- Enhancing productivity across diverse industries

Innovation plays a vital role in economic recovery. The deployment of robots signifies a shift toward leveraging technology for improved operational outcomes. This integration not only supports businesses but also aids economies in bouncing back from crises. By embracing technological solutions, societies can navigate through ongoing economic challenges with resilience and adaptability, paving the way for a more robust future.

The Current Economic Situation

The global economy is facing significant challenges, mainly due to the ongoing effects of the COVID-19 pandemic. Here are some key issues:

1. Global Recession

Many countries are currently experiencing a recession, with their GDP growth rates either remaining stagnant or declining.

2. Unemployment Rates

As of early 2023, the global unemployment rate is around 6%. However, in some regions, youth unemployment has exceeded 14%. This highlights the urgent need for creating jobs and revitalizing the economy.

3. Inflation

Countries are struggling with inflation rates that are at historic highs, often exceeding 8%. This means that prices for essential goods and services are rising, putting a strain on household budgets and consumer confidence.

The recent crises have had a widespread impact on various industries:

- Manufacturing has faced disruptions in its supply chain, resulting in delays in production.

- The hospitality sector is dealing with a shortage of workers as employees seek more stable job opportunities.

- Retail is experiencing changes in consumer behavior, with e-commerce trends becoming increasingly influential.

In this complicated situation, businesses and policymakers need to adapt in order to ensure resilience and growth. One potential solution to these economic challenges is the use of robots. By optimizing operations and improving productivity, robots can help businesses overcome obstacles and thrive. As economies work towards recovery and innovation amidst ongoing uncertainty, it is crucial to embrace technological advancements such as robotics.

Understanding Economic Challenges

Economic instability is driven by several factors impacting various sectors. Key contributors include:

- Supply Chain Disruptions: Global supply chains have faced significant interruptions, affecting product availability and increasing costs. Industries reliant on timely deliveries are particularly vulnerable.

- Labor Shortages: Many businesses grapple with a shortage of skilled labor, exacerbated by the pandemic’s effects. This shortage hampers operational capacity and slows down recovery efforts.

- Productivity Decline: As companies strive to adapt, productivity has taken a hit. Processes that were once efficient now face hurdles, further straining economic performance.

Sectors such as manufacturing, hospitality, and retail have been particularly impacted. Manufacturing struggles with both labor availability and supply chain issues, while hospitality and retail face challenges in staffing and customer engagement. Addressing these economic challenges is critical for paving the way toward recovery and stability.

The Role of Technology in Economics

Technology has always been a key driver of economic growth. From the Industrial Revolution to the digital age, new inventions have changed industries and made them more efficient. Right now, automation is leading the way, completely changing how businesses work.

Key Benefits of Automation:

- Efficiency Gains: Automation reduces human error and makes processes smoother, which can result in significant cost savings.

- Increased Productivity: Automated systems can run continuously, increasing output and enabling companies to meet rising demands.

- AI Integration: Combining artificial intelligence with automation creates smarter systems that can adapt and learn, further improving operations.

Countries that are using the first robots sent to help their economy are seeing these advantages up close. As industries embrace digital transformation, the move towards robotics represents a crucial moment in solving labor shortages and enhancing competitiveness across various sectors.

First Robots Dispatched to Tackle Economic Challenges

Types of Robots and Their Functions in Economic Recovery Efforts

The deployment of robotics in various economic recovery initiatives signifies a shift in how industries are addressing current challenges. Different types of robots are being utilized to enhance efficiency, productivity, and service delivery across sectors.

1. Industrial Robots

Industrial robots are at the forefront of automation in manufacturing. Their capabilities include:

- Assembly Line Automation: Performing repetitive tasks with precision.

- Quality Control: Utilizing advanced sensors for real-time monitoring and defect detection.

- Material Handling: Streamlining logistics by transporting goods efficiently within factories.

In sectors like automotive manufacturing, these robots have revolutionized production lines, significantly increasing output while reducing costs.

2. Service Robots

Service robots are increasingly deployed in customer-facing roles. Their applications include:

- Customer Support: Providing information and assistance through chatbots or interactive kiosks in retail environments.

- Healthcare Assistance: Supporting medical staff by managing logistical tasks or delivering medications within healthcare facilities.

- Hospitality Services: Enhancing guest experiences by providing room service or information at hotels.

These robots help businesses maintain high service standards while coping with labor shortages exacerbated by recent economic pressures.

3. Logistics Automation

In the realm of logistics, automation has become critical for efficiency. Key functions include:

- Warehouse Management: Robots manage inventory, picking, packing, and shipping processes with increased speed and accuracy.

- Delivery Systems: Drones and autonomous vehicles are being tested for last-mile delivery solutions, ensuring timely product availability.

This technology supports companies in adapting to increased demand for online shopping, particularly during recovery from the pandemic’s impact on traditional retail.

The integration of both industrial and service robots is transforming the operational landscape across sectors. Companies embracing these technologies are not only enhancing their competitive edge but also contributing to broader economic recovery efforts by optimizing resources and improving service levels.

By understanding the distinct functions of these robotic systems, businesses can better navigate the complexities of today’s economic environment while positioning themselves for future challenges. The role of robotics deployment is pivotal in creating resilient operational frameworks capable of adapting to ongoing changes within global markets.

Case Studies of Successful Implementation: Real-World Examples of Robots Helping Economies Bounce Back

Robots are being used in different industries to help economies recover. Here are some examples of where robots have been successfully implemented:

1. Amazon Robotics

In its warehouses, Amazon uses industrial robots to automate logistics tasks. These robots improve efficiency by handling inventory and speeding up the process of fulfilling orders. As a result, operational costs have significantly decreased and delivery times have improved.

2. SoftBank Robotics

Service robots like Pepper have been introduced in retail stores, revolutionizing how customers interact with businesses. These robots, deployed throughout Japan, assist shoppers by answering questions and suggesting products. Retailers have reported higher levels of customer satisfaction and engagement as a result.

3. Caterpillar

Caterpillar has integrated self-driving vehicles into its manufacturing facilities for transporting materials. This implementation has led to increased productivity as it reduces downtime and minimizes human errors, resulting in smoother operations.

These real-world examples demonstrate the concrete advantages of using robots during economic recovery efforts, showcasing their ability to enhance efficiency and boost productivity.

Benefits, Challenges, and Future Outlook: A Balanced Perspective on Using Robots for Economic Recovery

The integration of robots into various sectors presents numerous benefits that directly influence economic recovery. Key advantages include:

1. Increased Productivity

Robots can operate continuously without fatigue, leading to higher output levels. For instance, manufacturing plants utilizing robotic arms have reported production rates surpassing human capabilities, significantly boosting overall productivity.

2. Cost Reduction in Business Operations

Automation helps reduce labor costs and minimizes errors associated with manual processes. Companies incorporating robotic assistance often see a swift return on investment as operational efficiencies translate into substantial savings.

While the advantages are compelling, there are challenges that warrant consideration:

1. Public Perception Issues

The introduction of robots can create fear among the workforce regarding job security. Many employees worry about being replaced by machines, leading to resistance against automation initiatives.

2. Job Displacement Concerns

As robots take over repetitive tasks, certain job roles may diminish or become obsolete. Addressing these concerns is essential for ensuring a smooth transition toward an automated economy. It is crucial for businesses to invest in retraining programs and upskilling initiatives to prepare workers for new roles that robots cannot fulfill.

The future outlook for robotics in economic recovery remains promising but complex. Businesses must navigate the duality of leveraging robotic technology while addressing societal impacts. Striking this balance will be key in fostering an environment where both humans and robots can collaborate effectively to drive economic growth. As industries continue to evolve, it becomes increasingly important to engage in open dialogues about the integration of technology and its implications on the workforce.

Conclusion: Embracing Innovation And Technology As We Navigate Through Ongoing Economic Challenges With Help From Our Mechanical Allies!

The role of innovation for recovery with robotic assistance cannot be overstated. As we witness the first robots dispatched to help the economic situation, it’s essential to acknowledge both their potential and limitations.

Key considerations include:

- Balanced Approach: Relying solely on robotics may not be sustainable. It is crucial to integrate various solutions for economic resilience.

- Diverse Strategies: Embracing technology like automation should complement human efforts, ensuring that both systems work harmoniously.

- Future Preparedness: Building robust economies capable of weathering future storms requires collaboration between humans and machines.

By fostering an environment where technological advancements and human ingenuity coexist, society can navigate these challenges more effectively. The journey toward economic recovery is a collective endeavor, and innovation will pave the way forward.

FAQs (Frequently Asked Questions)

What are the current economic challenges that robots can help address?

Current economic challenges include global recessions, high unemployment rates, and inflation. Robots play a crucial role in addressing these issues by enhancing productivity, automating processes, and improving service delivery across various sectors.

How do robots contribute to economic recovery initiatives?

Robots contribute to economic recovery initiatives by being deployed in industries facing labor shortages and supply chain disruptions. They perform essential functions such as logistics automation, customer support through service robots, and boosting overall efficiency in manufacturing.

What types of robots are being used for economic recovery efforts?

There are several types of robots being utilized for economic recovery, including industrial robots for manufacturing processes, service robots for customer interaction, and logistics automation robots that streamline supply chains. Each type serves specific functions tailored to the needs of different sectors.

Can you provide examples of successful robot implementations in the economy?

Yes! Successful implementations include warehouses using robotics to enhance efficiency and reduce operational costs. Specific case studies highlight how these technologies have positively impacted productivity and helped businesses adapt during economic downturns.

What are the benefits and challenges associated with robotic integration in the economy?

Benefits of robotic integration include increased productivity, cost reduction in business operations, and improved service delivery. However, challenges such as public perception issues and potential job displacement concerns must be addressed to ensure a balanced approach to widespread robotics adoption.

Why is innovation important for navigating ongoing economic challenges with robotics?

Innovation is vital as it drives technological advancements that can lead to sustainable economic recovery. Embracing robotic assistance allows businesses to adapt more effectively to changing market conditions while fostering resilience against future economic crises.